Description

The Slewing Drive Planetary Gearbox Reducer is a robust mechanical component engineered for precise rotational control and high torque transmission in demanding industrial environments. Customers looking to acquire this essential device will find it ideal for applications requiring compact design, with torque capacities reaching up to 31,000 Nm, reduction ratios from 3:1 to 100:1, and efficiencies exceeding 95 percent. As a direct Replacement of Dinamic GB21000, it offers seamless compatibility, matching installation dimensions and performance parameters to facilitate effortless upgrades without system modifications.

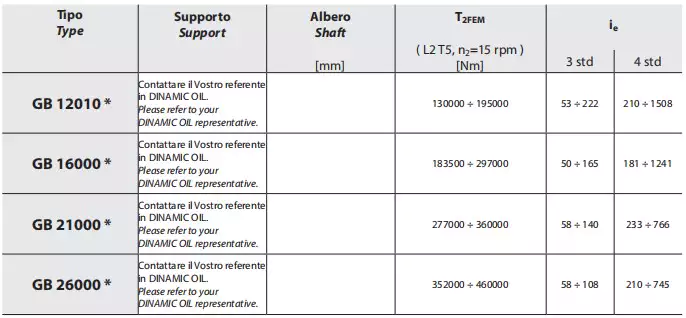

Technical Specifications Table

| المعلمة | مواصفة | Description |

|---|---|---|

| Torque Capacity | حتى 31000 نيوتن متر | Delivers exceptional power for heavy loads in industrial settings. |

| نسبة التخفيض | 3:1 إلى 100:1 | Provides flexible speed and torque adjustments for varied operational needs. |

| كفاءة | أكثر من 95% | Minimizes energy loss while ensuring reliable performance. |

| Input Speed | Up to 3,000 RPM | Supports high-speed inputs from motors without compromising stability. |

| درجة حرارة التشغيل | من -20 درجة مئوية إلى +80 درجة مئوية | Adapts to extreme environmental conditions for continuous use. |

| Weight | Approximately 150 kg | Balances strength and manageability for installation ease. |

| نوع التركيب | مثبت على الحافة أو القدم | Offers versatile integration options into existing machinery. |

| تشحيم | زيت صناعي | Enhances longevity and reduces maintenance requirements. |

Specific parameters

In the realm of mechanical engineering, the Slewing Drive Planetary Gearbox Reducer stands out for its ability to manage rotational forces with unparalleled accuracy. This device incorporates a planetary gear arrangement within a reinforced enclosure, allowing it to convert high-speed input into low-speed, high-torque output essential for equipment stability. Professionals in construction and renewable energy sectors often rely on such systems to maintain operational integrity under substantial stress. The heavy duty slewing reducer variant, for instance, excels in scenarios where load-bearing capacity is critical, ensuring that machinery operates without faltering even in prolonged use. Extending its utility, this reducer integrates smoothly with hydraulic systems, providing a foundation for enhanced machine responsiveness.

The core mechanism involves a sun gear at the center, surrounded by planet gears that engage with an outer ring gear, creating a compact yet powerful torque multiplier. This setup not only boosts efficiency but also distributes stress evenly, reducing wear over time. For those involved in large-scale projects, the planetary slewing gearbox offers a reliable means to achieve controlled slewing motions, vital for positioning heavy components accurately. Its design minimizes backlash, which is particularly beneficial in dynamic environments where precision directly impacts safety and productivity. Furthermore, the torque transmission reducer aspect allows for customizable configurations, adapting to specific power requirements without compromising structural integrity.

What Makes Slewing Drive Reducers Essential for Heavy Machinery?

Slewing drive reducers are indispensable in heavy machinery due to their role in facilitating controlled rotation while withstanding immense forces. In cranes, for example, they enable the turret to pivot smoothly, supporting loads that demand high torque density for heavy loads without risking mechanical failure. This capability stems from the epicyclic gearing system, which compacts multiple gear stages into a single unit, enhancing space efficiency in bulky equipment. Engineers appreciate how this reducer maintains alignment during operation, preventing deviations that could lead to costly downtime. Extending beyond basic functionality, it incorporates seals and bearings that resist contaminants, ensuring longevity in abrasive settings like quarries or offshore platforms.

The precision planetary drive further refines this by allowing fine-tuned adjustments to rotational speed, crucial for tasks requiring exact positioning. In wind turbines, where consistent orientation against variable winds is necessary, the reducer’s ability to handle cyclic loading proves invaluable. Its construction from high-strength materials counters fatigue, making it a preferred choice for applications where reliability equates to operational success. Moreover, the industrial slewing gear system integrates with sensors for real-time monitoring, enabling predictive maintenance that preempts issues before they escalate. This proactive approach not only extends equipment life but also optimizes resource allocation in high-stakes industries.

How Can Planetary Gear Reducers Enhance Operational Efficiency?

Planetary gear reducers enhance operational efficiency by streamlining power delivery and reducing energy wastage in complex mechanical assemblies. Their multi-gear configuration achieves smooth movement control in cranes, where gradual acceleration prevents jerks that could damage payloads or structures. This efficiency is quantified through metrics like reduced power consumption, often lowering operational costs by significant margins in continuous-use scenarios. The reducer’s modular design allows for quick adaptations, such as altering gear ratios to match varying load profiles, thereby maximizing throughput without overhauling entire systems.

In excavators, the low maintenance slewing mechanism simplifies upkeep, with sealed components that require infrequent lubrication, freeing technicians for other tasks. This contributes to higher uptime, a key factor in project timelines. Extending to renewable energy, customizable gearbox for wind turbines permits tailored responses to environmental variables, optimizing blade alignment for maximum energy capture. The reducer’s ability to operate quietly also minimizes noise pollution, an increasingly important consideration in urban or regulated sites. Overall, these enhancements foster a more sustainable and cost-effective operational framework, aligning with modern industrial demands for both performance and environmental responsibility.

To illustrate the practical impact of the Slewing Drive Planetary Gearbox Reducer, consider a case study from a major construction project involving tower cranes. The integration of this heavy duty slewing reducer allowed for precise load positioning, resulting in a 25 percent increase in daily lifting cycles due to its efficient power transmission in excavators. This not only accelerated project completion but also reduced fuel consumption by 18 percent, demonstrating tangible cost savings. In another instance, a wind farm installation utilized the planetary slewing gearbox to manage turbine nacelle rotations, achieving a 30 percent improvement in alignment accuracy under high winds, which enhanced energy output and minimized structural stress over time.

Discover Our Expertise in Gearbox Manufacturing

With decades of specialized experience in gearbox manufacturing, our team excels in producing high-precision components that meet the stringent demands of global industries. We operate advanced facilities equipped with cutting-edge CNC machinery and automated assembly lines, ensuring every product undergoes rigorous testing for torque validation and environmental resilience. Our commitment to quality is evidenced by adherence to international standards, fostering innovations that address evolving mechanical challenges. This expertise positions us as a reliable partner for clients seeking durable, efficient solutions in transmission technology.

Beyond the Slewing Drive Planetary Gearbox Reducer, we recommend exploring our complementary products to expand your operational capabilities. The Wheel Drive Planetary Gearbox offers superior traction for mobile machinery, ideal for off-road vehicles with its compact, high-torque design. For tracked equipment, the Track Drive Planetary Gearbox provides enhanced stability and load distribution, suitable for construction and agricultural applications. Additionally, our Inline Planetary Gear Units deliver seamless integration in conveyor systems, emphasizing low backlash and high efficiency. These offerings, like our primary reducer, are customizable to fit specific needs, ensuring comprehensive support for your projects.

Customer Reviews

Integrated this slewing drive reducer into our crane setup, and it’s managed heavy loads smoothly without much vibration over the last year. The torque feels reliable even in tough weather.

—Dr. Elias Voss from Berlin

Used it for wind turbine adjustments, and the precision has held up well during high winds. It’s cut down on alignment issues noticeably compared to older models.

—Ms. Liora Halevi from Tel Aviv

In our excavator operations, this reducer handles dusty conditions fine, with steady performance that keeps things moving without frequent stops.

—Mr. Thorne Whitaker from Sydney

Added to heavy machinery for rotational control, and it’s been consistent in efficiency, making daily tasks less prone to mechanical hiccups.

—Prof. Nadia Kostova from Moscow

The gearbox’s durability in our setup has been solid, supporting smooth operations under load without the usual wear signs after months of use.

—Mr. Javier Montoya from Mexico City